A fume hood is made up of a hood body; baffles, which are partitions used to create slotted openings along the back of the hood body; airfoils, which stream-line airflow into the hood; the work surface; an exhaust plenum, which helps to distribute airflow evenly across the hood face; the face; and the sash.

Fume Hood Sashes: What Are They?

The sash refers to the front window or “door” of a fume hood. The glass window slides open and closed, allowing access to the workstation. The sash window provides both containment and protection from hazardous materials.

Because fume hoods are constantly working to filter the air, they can use as much energy in a day as three or four residential homes when the sash is open.

There are two types of fume hood exhaust systems; constant air volume (CAV) and variable air volume (VAV). Constant air volume ventilation provides a constant flow of air, whether the sash is open or not. Closing the sash on a CAV hood will increase the face velocity, which could potentially push contaminated air back into the room.

A minority of fume hoods have VAV ventilation. These hoods vary the volume of air from the room that is exhausted while maintaining the face velocity at a predetermined level. The vented air volume is controlled by the sash height, so a lower sash means lower air exhausted to save energy and expenses. When the sash is closed, VAV systems are employed, which reduces the volume of the air exhausted.

Though the VAV system conserves more energy, it costs much more than the CAV system.

Types Of Fume Hood Sashes

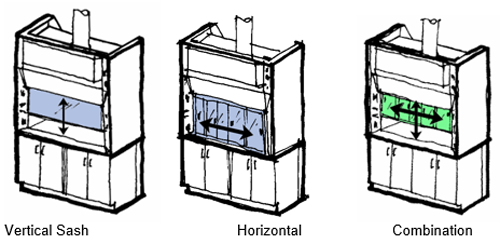

There are three types of fume hood sashes: vertical, horizontal, and combination vertical and horizontal.

“Renovating Research Laboratories by Dan Watch. National Institute of Building Sciences”

- Vertical sashes are the most common. They provide the most access to the workstation because the window slides up and down.

- Horizontal sashes slide from left to right, allowing a user to position themselves behind the sash for protection while enabling access through the sides. They provide the best access to the top interior of the hood but do not provide access to the entire width at the same time.

- Combination sashes combine horizontal sash panes, in a vertical rising frame. They offer the advantages of both vertical and horizontal sashes.

Sash Window Safety

The sash works as a blast shield to provide protection and containment in the event of a fire. In the case of an explosion, sashes are designed to “spiderweb” instead of shattering, keeping those in the area safe from glass and chemicals. There are two main types of glass used for a fume hood sash: tempered and laminated safety glass. For specific applications, polycarbonate may be used.

- Tempered glass can withstand impacts five times stronger than ordinary glass. When it is broken, it shatters into small, blunt pieces to prevent serious injury. Tempered glass has high heat shock resistance, meaning it can withstand radical changes in temperature of up to 200 degrees C, compared to 70 degrees C for ordinary float glass.

- Laminated safety glass is comprised of two pieces of float glass with a layer of polyvinyl butyral (PVB) between them. Pressure and heat are applied to bond the layers together. When this type of glass breaks, the shards tend to adhere to the PVB layer inside, affording protection from flying or falling pieces of glass.

- Polycarbonate is a substitute for a glass sash for situations that require working with Hydrofluoric Acid. Hydrofluoric Acid etches glass, so using it in a standard hood over time will eventually require sash replacement. Polycarbonate can be installed on most fume hood types, as long as the liner material is compatible with Hydrofluoric Acid.

How Do I Use A Fume Hood Sash?

When using a fume hood, there should be arrows located on the sash to indicate at what height the window should be raised. The sash should only be opened all the way to place materials on the workstation. While in use, the hood should never be raised above the user’s head, nor should a user place their head inside the hood opening. For vertical rising sashes, keep the sash below your face. For horizontal sliding sashes, keep the sash positioned in front of you and work around the side of the sash.

While working on the work surface, all materials should be kept inside the hood at least six inches from the sash. In case of an emergency, an object in the way of the sash would keep it from closing quickly. A fume hood is not designed to contain high-velocity releases of contaminants unless the sash is fully closed.

Also, chemicals should never be permanently stored inside the hood. These are safety measures that should be taken in case of an explosion.

Interested in learning more about fume hoods? Check out these articles:

How Much Does a Fume Hood Cost?

Choosing the Right Liner Material for Your Fume Hood

Understanding the Importance of Fume Hood Baffles